Tooling Solutions

Hole making

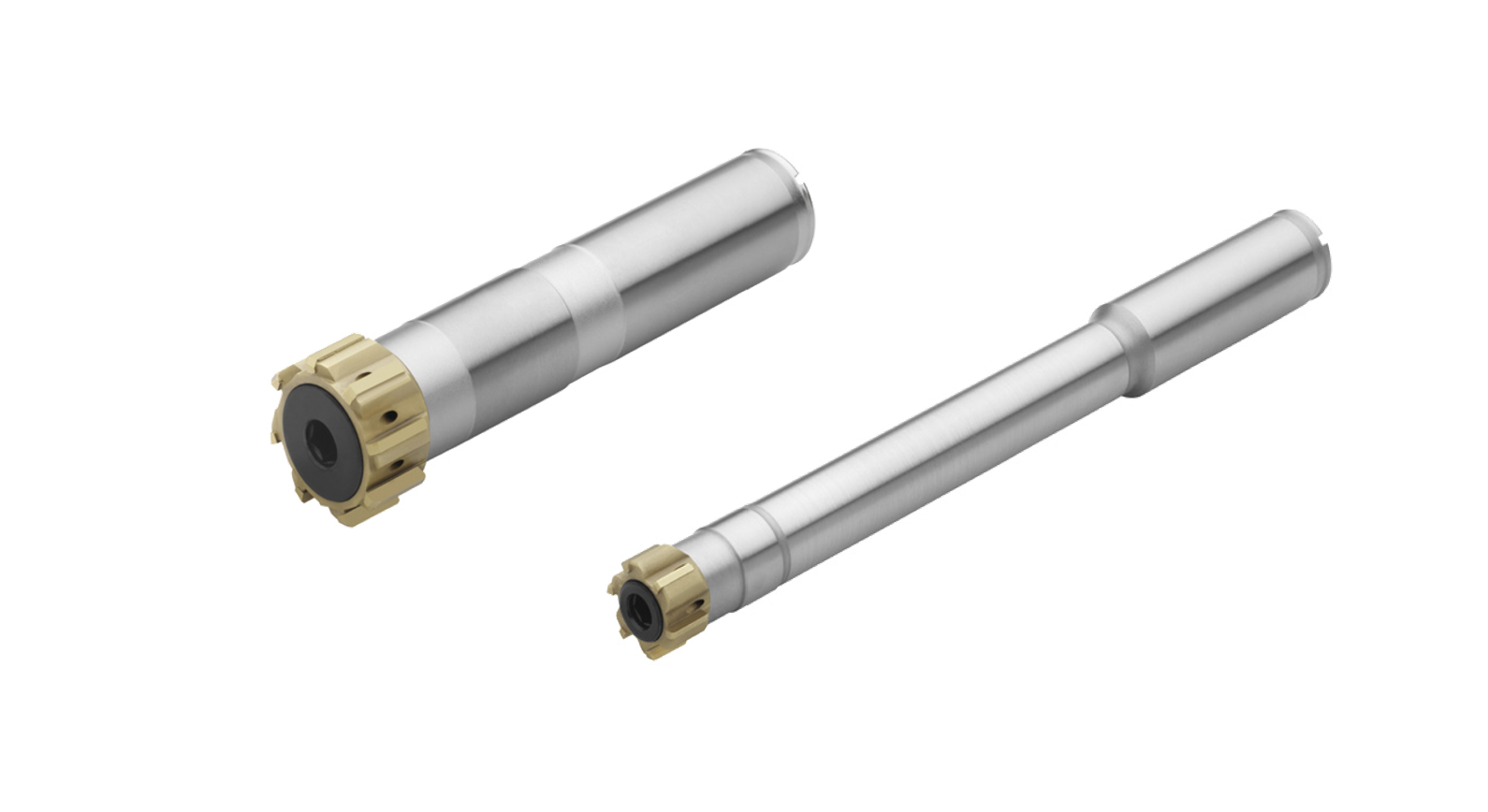

Reaming

Threading

Precision tools for tapping, thread forming and thread milling.

WMPS high accuracy reaming tools for your best performance.

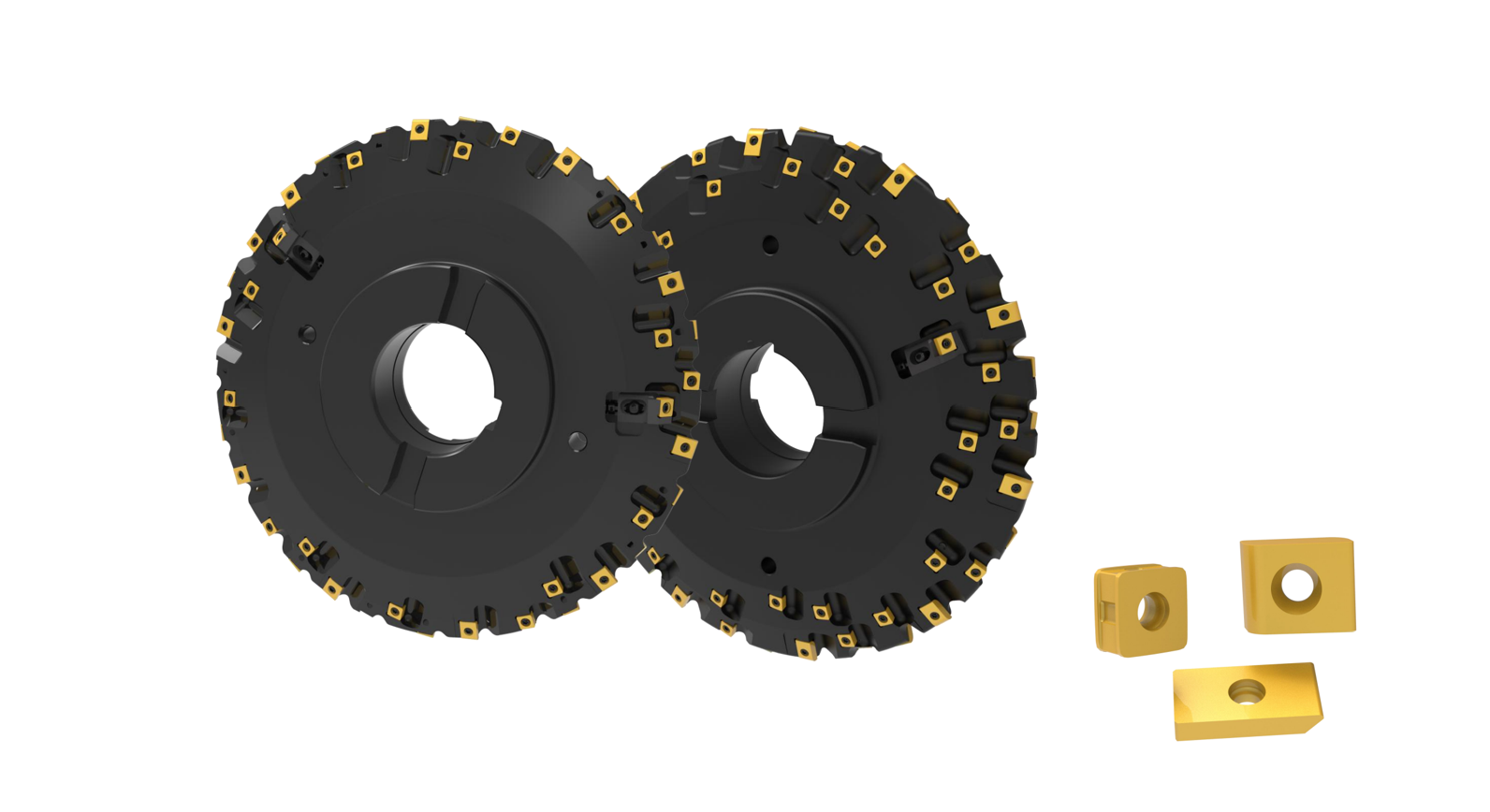

ghtools premium tools for solid drilling, counterboring.

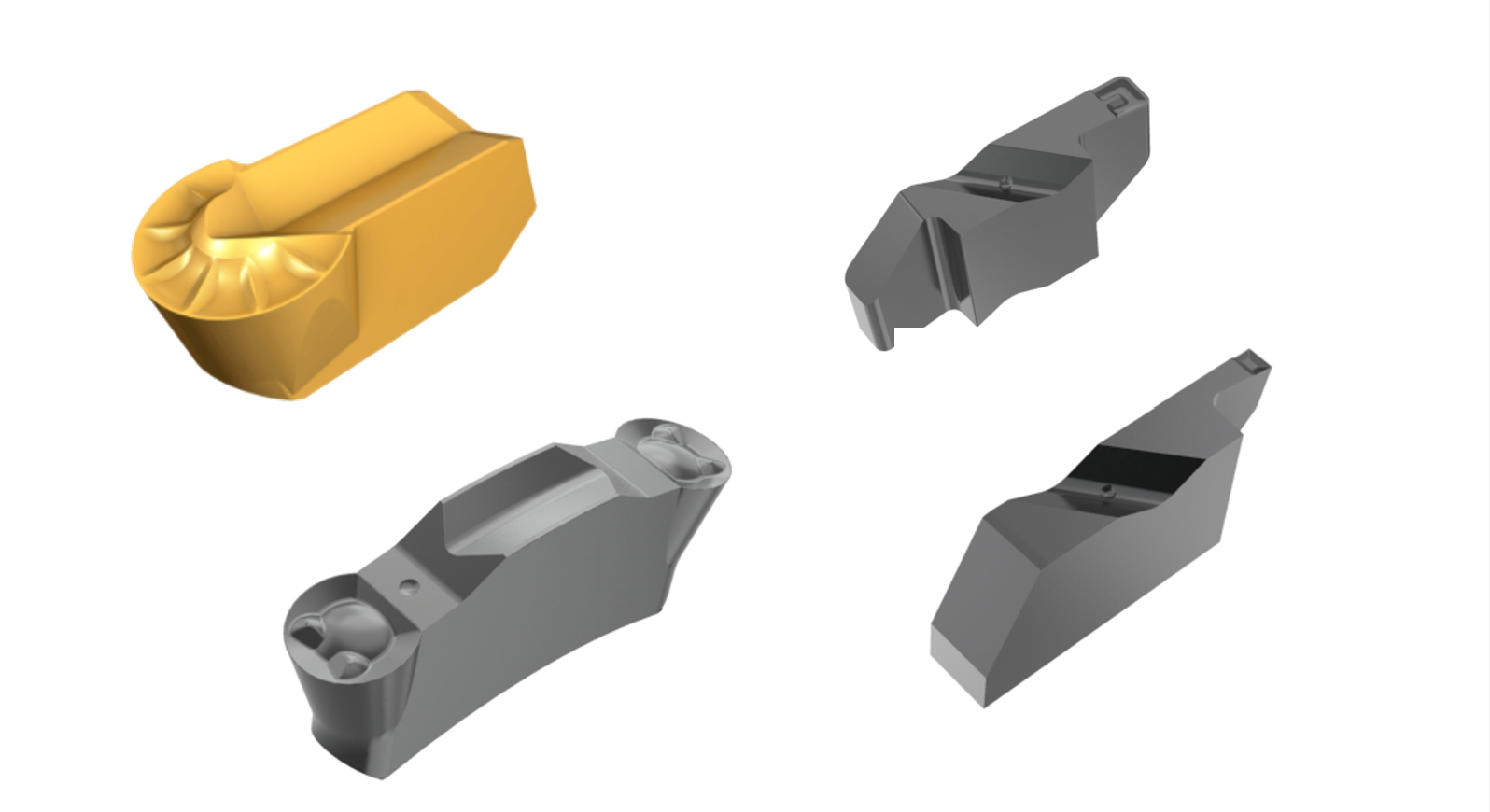

Special insert customized

PCD&PCBN tool customized

Speical tool customized

Design and develop non-standard blades based on your specific needs and the machining characteristics of the components.

ghtools PCD tools for Automotive and aerospace industry.

Design and develop special tools based on your specific needs and the machining characteristics of the components.

Industry Solutions

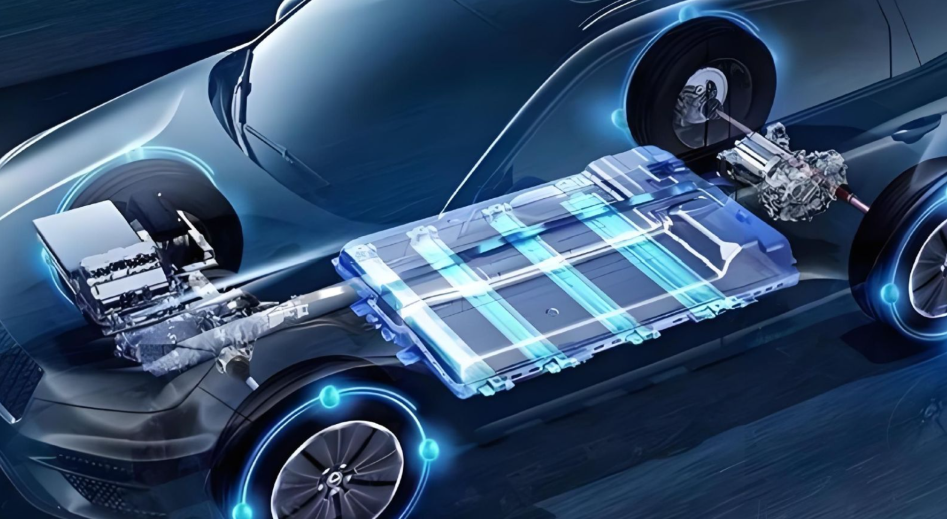

Automotive

Energy

Aerospace

By equipping with the most advanced blade manufacturing technology and equipment, we provide more choices for your aerospace manufacturing.

Faced with the increasing difficulty and quality requirements of parts manufacturing in fields such as oil and gas, wind power, and power generation, the project engineering team utilizes the most advanced cutting tools to ensure safe and efficient production.

The constantly changing market has put forward new requirements for automobile manufacturing. Our aspiration is to provide you with solutions that meet your needs for quality, reliability, and reducing the cost of individual parts.

Our Factory

WMPS Precision Technology Co., Ltd.

POLTAVA DIAMOND TOOLS

The factory is located in Taicang, known as the "hometown of German enterprises", and mainly produces precision reaming tools, electrically controlled motion tools, and tool control systems adapted to machines for precision machining in the mechanical industry.

PDTOOLS was founded in 1966, specialize in the production of diamond and CBN tools for various industries.

News

ghtools

Company

Engineering Competence

Reduce processing cost

GHTOOLS Precision Technology Co., Ltd. is a professional provider of metal cutting technology solutions and a full range of products. The technical team is composed of engineers with over ten years of professional experience, covering fields such as tool design, tool manufacturing, and tool application. Thanks to a professional team of engineers, ghtools can accurately match customer needs, providing reliable products and professional application services for customers from raw materials for tool production including hard alloy rods, polycrystalline diamond (PCD), cubic boron nitride (PCBN), and synthetic diamond (CVD Diamond), to hard alloy tools, polycrystalline diamond (PCD) tools, polycrystalline cubic boron nitride (PCBN) blades, and reversible steel product tools. We have deep cooperation with high-quality suppliers in China, from raw material formulation to tool production design, with technical engineers involved in every key step that may affect the quality of the cutting edge.

We provide customers from around the world with a complete set of process and tool solutions, including product and layout design, reasonable arrangement of processing technology, accurate calculation of processing cycle, and overall optimization of process and product. The engineering team has provided perfect machining solutions and product support for customers from the automotive, new energy, and engineering hydraulic industries, such as the machining of steering knuckles, shock forks, and connecting arms in automotive chassis; Processing of motor housing and battery bracket for new energy vehicles; Special hydraulic valve body processing for construction machinery, especially for the processing of bi-directional stainless steel valve bodies used for underground operations. My project engineering skills provide clients with support during sample production and mass production processes, helping them solve difficult problems during the processing.

Our goal is to help customers reduce the cost of using machining tools. Thanks to the leapfrog development of China's machinery manufacturing industry in the past 10 years, the supporting tool industry chain has also undergone rapid changes, and the gap between its performance and that of top European brands has gradually narrowed. As a solution integrator based in China and providing professional project engineering and technical services to global customers, we have been committed to helping overseas customers match the most suitable tool products and application solutions, perfectly replacing expensive mainstream brand products, and achieving the core concept of reducing tool usage costs.